For top-and-down bi-beam measurement of wafer bare disks, it is compatible with up to 8in wafers

Supports multiple sensors and up to 3 probe sensors simultaneously

Measurement accuracy<<0.5um (if the sample surface roughness difference is too large, there will be error fluctuations)

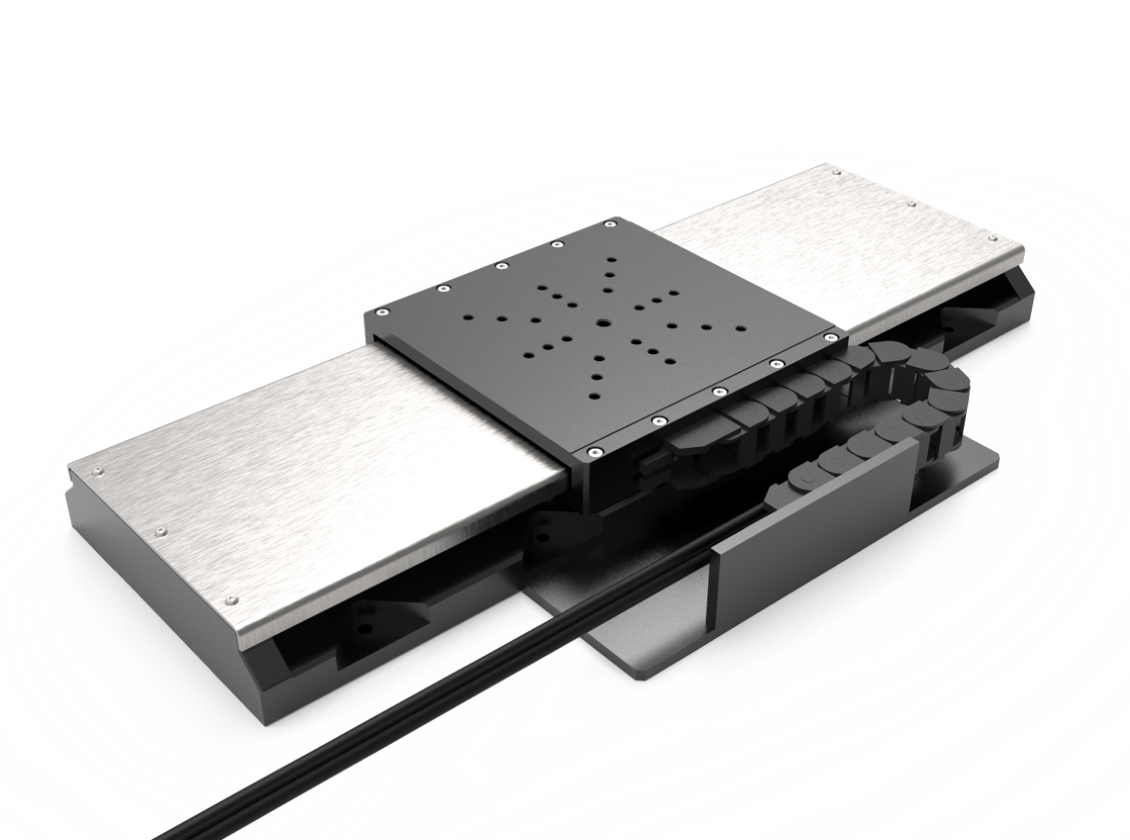

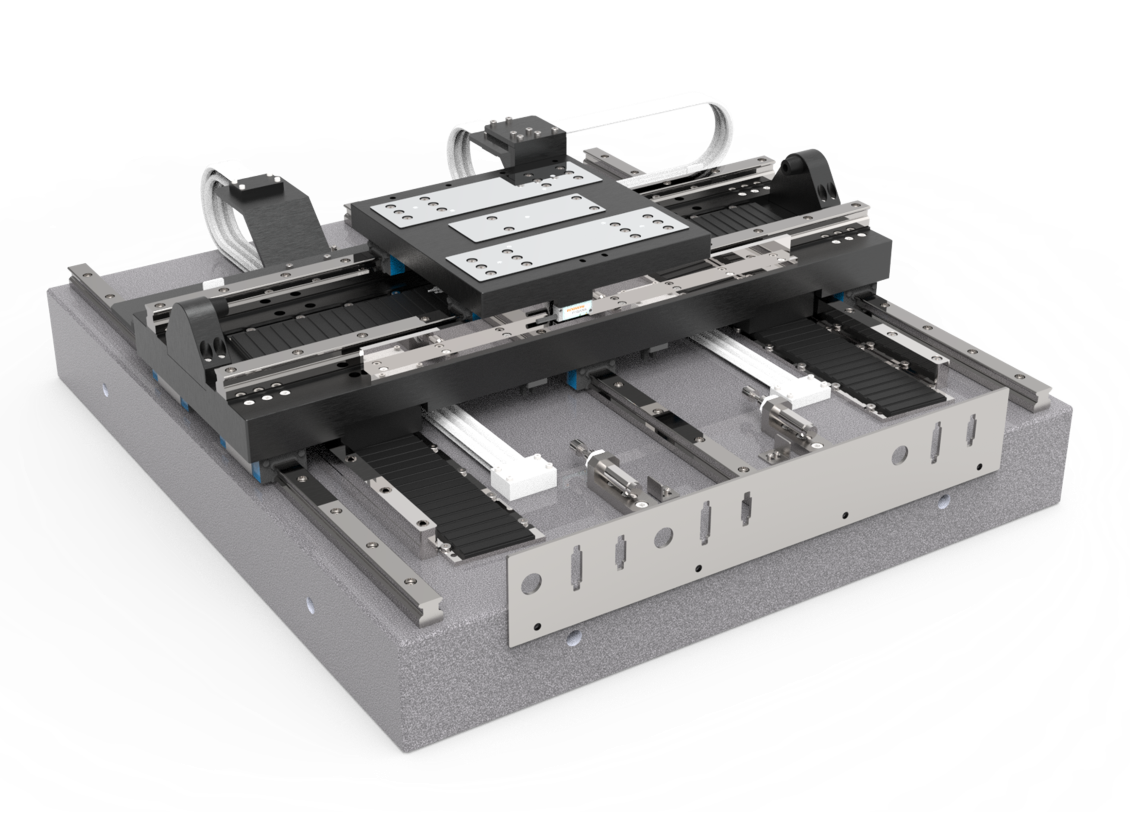

It adopts linear motor + air floating guide rail gantry motion mechanism, which has high precision and supports long-term continuous work

Automatic positioning of wafer position on substrate with visual aid

Support custom editing of measurement points

Upgraded and optimized system vibration isolation mechanism, testing is not sensitive to environmental requirements

Z-axis optimized closed-loop with grating function for extended measuring range (sensor measuring stroke 1 mm, expandable up to 40 mm position)

Touch screen function use

MES system interface docking communication upthrow customization

Automatic standard precision correction

The manipulator automatically loads and unloads

Support post-detection sorting and sorting

Standard model supports 2 boxes of crystal boats (expandable to 4 boxes)

Optional wafer angle calibration table (wafer edge patroller)

Optional upgrade function BOW/WRAP/SORI/ film stress and other upgraded software analysis functions